Stamping Center

Large tonnage stamping area

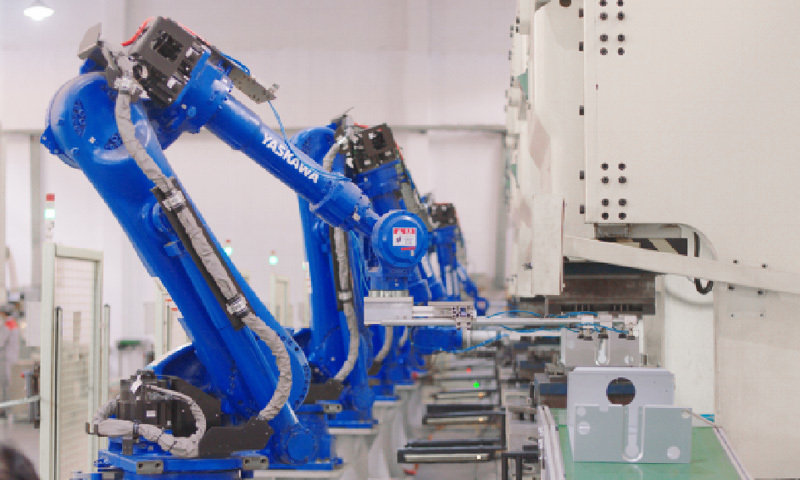

Continuous die production line

Automatic stamping production line

Sheet Metal Center

Sheet metal production workshop

CNC stamping area

Bend Area

Welding Center

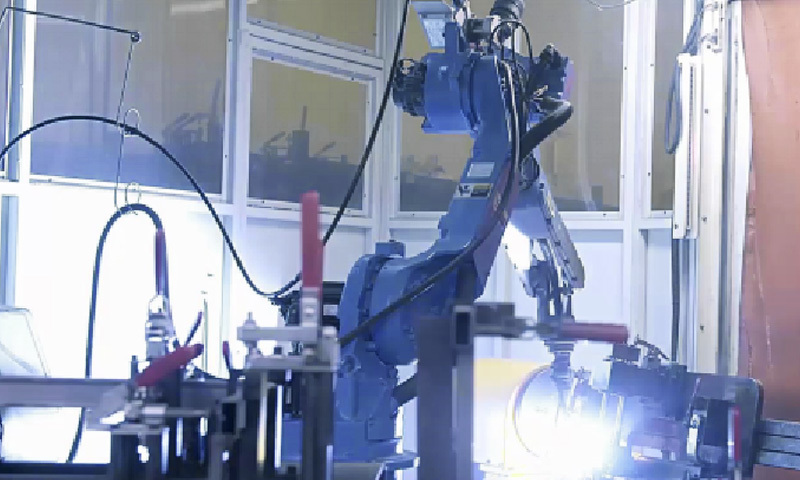

Robot welding area

Manual welding area

Manipulator welding

machining center

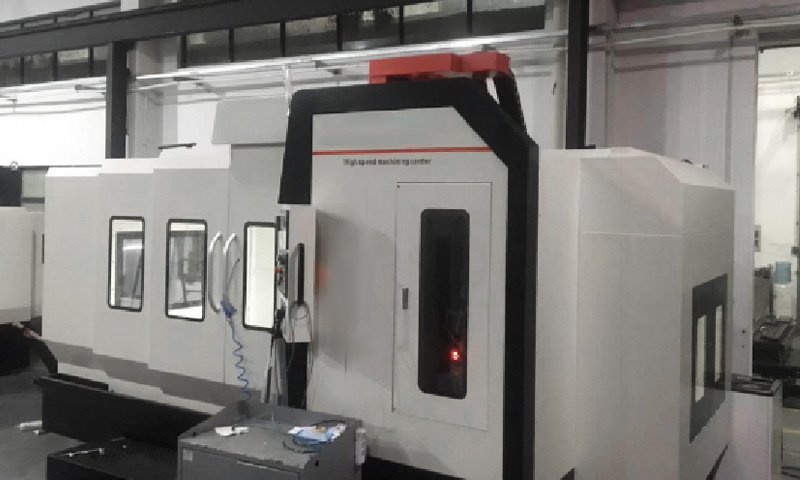

Machine workshop

Horizontal Machining Center

Wire cutting equipment

Assembly Center

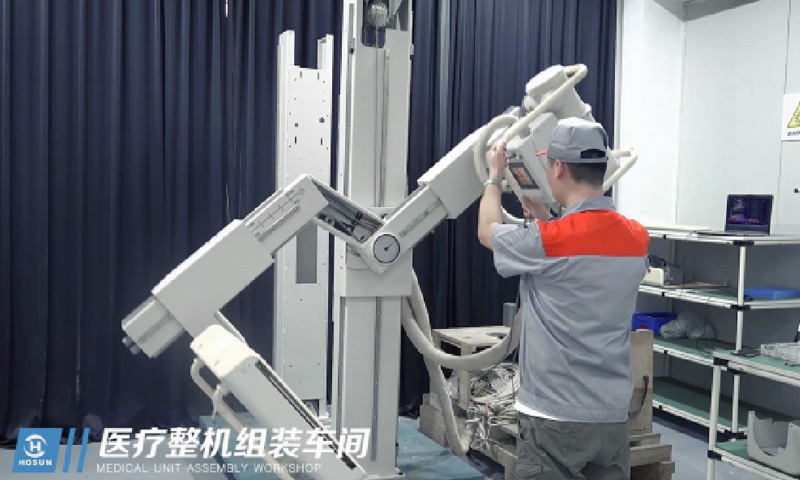

Medical Assembly Area

Complete machine testing center

Medical Assembly Area

Spraying center

Automatic spraying line

Hand spraying

Storage area

Testing Center

Simulate the actual movement of the product and test the parameters of product operation, noise, tension, etc.